Knowledge

What Makes a High-Quality Scaffolding Coupler? Key Features for Safety and Efficiency

What Makes a High-Quality Scaffolding Coupler? Key Features for Safety and EfficiencyIntroduction

Scaffolding couplers may be small components, but they play an indispensable role in ensuring the safety and stability of temporary structures in construction projects. These connecting devices join scaffolding tubes together, forming secure frameworks that support workers and materials at various heights. Understanding what distinguishes superior scaffolding couplers can mean the difference between a safe, efficient project and a potential hazard. This article explores the essential characteristics that define high-quality scaffolding couplers and why they matter for construction professionals.Material Composition and Durability

The foundation of any reliable scaffolding coupler begins with its material composition. High-grade steel and malleable iron are common materials used in manufacturing due to their exceptional strength and durability. For environments where corrosion resistance is crucial, such as coastal areas or industrial settings, galvanized steel couplers provide added protection against rust and degradation. Some specialized couplers are made from aluminum alloys, offering a lighter-weight alternative while maintaining structural integrity. The material choice directly impacts the coupler's lifespan and performance under stressful conditions, including heavy loads and harsh weather exposure.

Premium couplers undergo specialized treatments and coatings to enhance their durability. These protective layers significantly increase resistance to environmental factors, ensuring consistent performance throughout extended project timelines. The material quality should comply with international standards such as BS EN 74, which specifies rigorous requirements for couplers used in temporary works structures.

Structural Design and Load Capacity

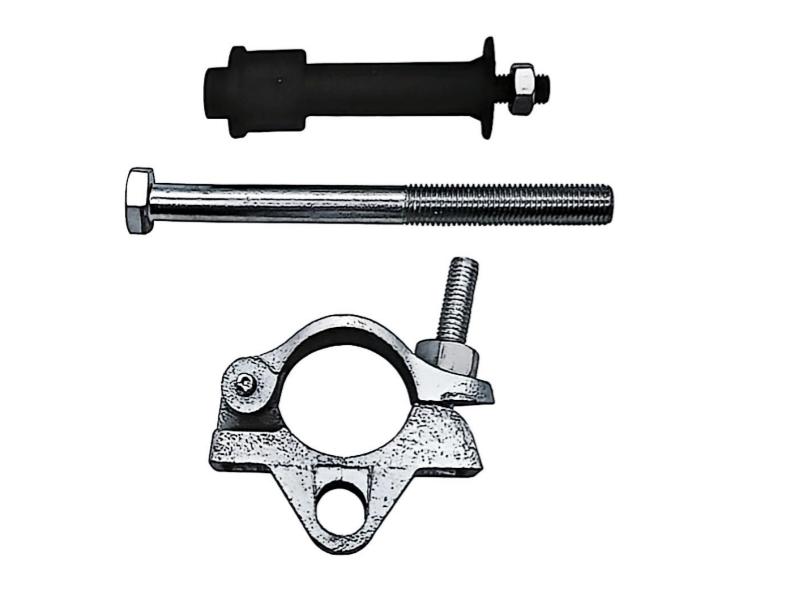

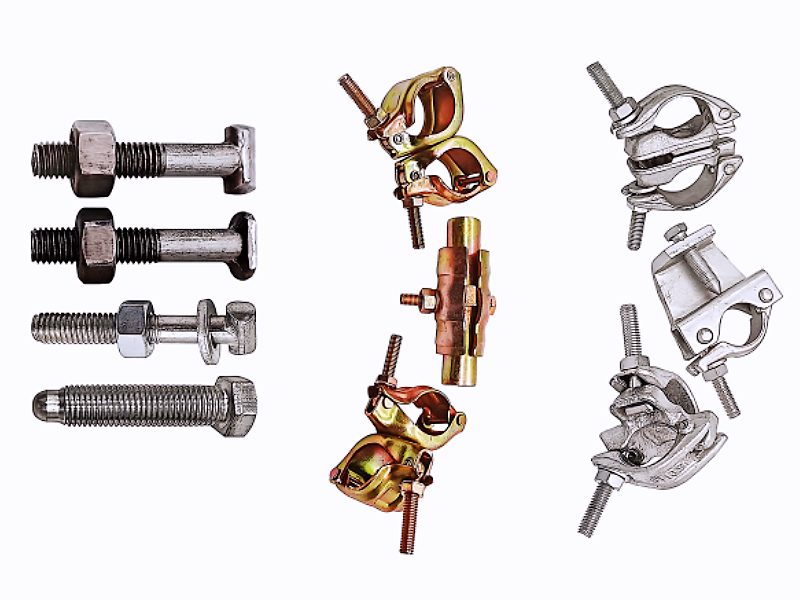

The engineering design of scaffolding couplers determines their functionality and safety margins. Different coupler types serve specific purposes in scaffolding configurations:Right Angle Couplers: Designed to connect tubes at 90-degree angles, providing secure perpendicular joints

Swivel Couplers: Allow for flexible connections at various angles, ideal for irregular structures and complex configurations

Sleeve Couplers: Join tubes end-to-end in straight connections, essential for extending scaffold length

Putlog Couplers: Specifically used to connect putlogs (horizontal supports) to ledger pipes

Quality couplers are engineered to distribute weight evenly across the structure, preventing localized stress points that could lead to failure. According to standards like BS EN 74-2:2022, half couplers are classified by load capacity, with Class B couplers required to withstand slipping forces of at least 15.0 kN and failure forces of 30.0 kN—significantly higher than the 10.0 kN and 20.0 kN requirements for Class A respectively. These specifications ensure the couplers can handle the dynamic loads encountered in real-world construction scenarios.

Safety Features and Certification Compliance

Superior scaffolding couplers incorporate built-in safety mechanisms that prevent accidental dislodgement. Many feature specialized locking systems that maintain secure connections even under vibration or impact. These design considerations are critical for preventing accidents on site and ensuring worker safety at elevation.

Reputable coupler manufacturers adhere to stringent international standards and certification processes. Key certifications to look for include:

BS EN 74: European standard specifying requirements for special couplers used in falsework and scaffolds

OSHA regulations: Occupational Safety and Health

Administration guidelines for workplace safety JIS (Japanese Industrial Standards): Quality specifications for materials and dimensions

SNI (Standar Nasional Indonesia): Mandatory standards for construction projects in Indonesia These certifications ensure that the couplers have undergone rigorous testing for slipping force, failure force, and bending moment capacity. For instance, BS EN 74-2:2022 mandates standardized testing methodologies where a minimum of 10 samples undergo slipping force tests to verify performance consistency.

Corrosion Resistance and Environmental Adaptability

The ability to withstand environmental challenges is a hallmark of quality scaffolding couplers. Galvanized coatings provide essential protection against moisture, chemicals, and atmospheric corrosion that can compromise structural integrity over time. This is particularly important for projects in humid climates, coastal areas, or industrial environments where corrosive elements are present. The corrosion resistance directly impacts both safety and cost-effectiveness. Well-protected couplers maintain their strength and functionality through multiple projects, reducing replacement frequency and minimizing the risk of structural failures due to material degradation. Regular visual inspections should check for signs of rust, wear, or bending that might indicate the need for replacement.

Ease of Installation and Maintenance

Practical considerations like installation efficiency significantly contribute to a coupler's overall value. High-quality couplers are designed for straightforward installation and removal, facilitating quick scaffold assembly and disassembly. This user-friendly design translates to substantial time savings on projects, reducing labor costs and improving project timelines. Maintenance requirements also factor into the quality equation. While galvanized couplers offer superior corrosion resistance, proper storage in dry, secure areas remains essential for prolonging their lifespan. Established inspection protocols should include checking for deformation, thread damage, or wear before each use. Couplers that have undergone significant stress or show visible signs of wear should be retired from service to maintain safety standards.

Weight Considerations and Compatibility

The physical characteristics of scaffolding couplers, including their weight, impact their practicality on site. Standard weights for standard coupler types include:

Right Angle Couplers: Approximately 1.34 kg each

Swivel Couplers: Approximately 1.49 kg each

Sleeve Couplers: Approximately 1.88 kg each

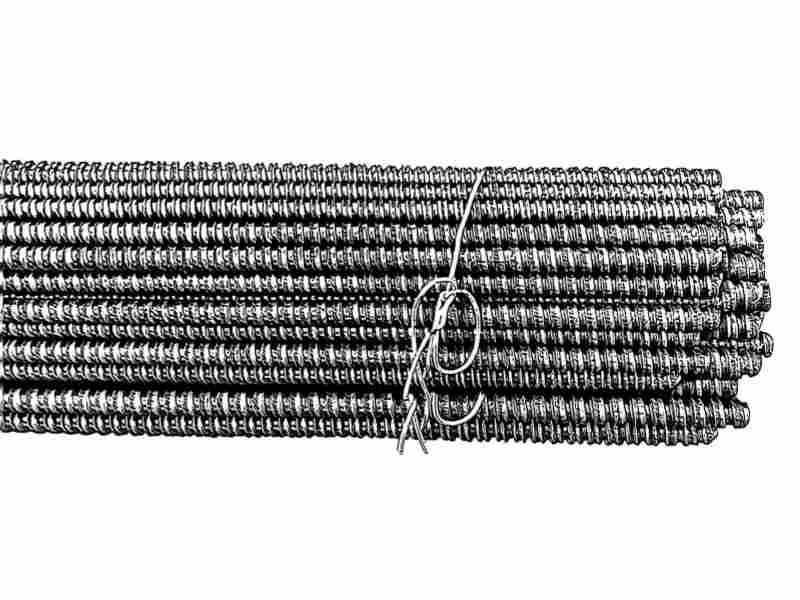

These standardized weights help project managers calculate load distributions and transportation requirements accurately. Compatibility with standard scaffolding tubes is another critical factor. Quality couplers are designed to integrate seamlessly with commonly used tube diameters (typically 48mm with 3.5mm wall thickness). This ensures tight, secure connections without gaps or misfits that could compromise structural stability. The internal structure of premium couplers includes precisely machined channels and grooves that guarantee proper fitting with the connected components.

Conclusion: Selecting the Right Scaffolding Couplers

Identifying superior scaffolding couplers requires careful evaluation of multiple factors. The ideal coupler combines high-strength materials, robust engineering design, adequate load capacity, comprehensive certifications, and environmental resilience. Beyond technical specifications, practical considerations like ease of installation, maintenance requirements, and compatibility with existing equipment significantly influence their effectiveness in real-world applications. Investing in quality scaffolding couplers pays dividends through enhanced safety, reduced accident risk, and improved project efficiency. By prioritizing couplers that meet international standards and demonstrate proven performance characteristics, construction professionals can build with confidence, knowing their temporary structures provide a secure foundation for successful project completion. As technology advances, we can expect continued innovation in coupler design, including smarter monitoring systems and even stronger, lighter materials. However, the fundamental principles of quality—superior materials, precise machining, and rigorous testing—will remain the constant foundation of scaffolding safety and reliability.